Global Industry 4.0 Market, By Component, By Technology, By Industry Vertical, By Region & Segmental Insights Trends and Forecast, 2024 – 2034

- Industry: Technology

- Report ID: TNR-110-1190

- Number of Pages: 420

- Table/Charts : Yes

- June, 2024

- Base Year : 2024

- No. of Companies : 10+

- No. of Countries : 29

- Views : 10290

- Covid Impact Covered: Yes

- War Impact Covered: Yes

- Formats : PDF, Excel, PPT

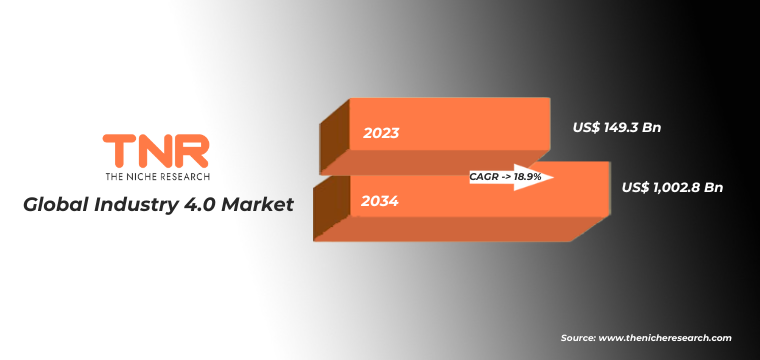

In Terms of Revenue, the Global Industry 4.0 Market was Worth US$ 149.3 Bn in 2023 and is Anticipated to Witness a CAGR of 18.9% During 2024 – 2034.

Industry 4.0 refers to the current trend of automation and data exchange in manufacturing technologies. It encompasses cyber-physical systems, the Internet of Things (IoT), cloud computing, and cognitive computing. This transformation allows for smart factories where machines can communicate with each other autonomously and make decentralized decisions. The Industry 4.0 market is rapidly expanding, driven by the increasing adoption of smart manufacturing techniques across various industries.

Key trends include the integration of AI and machine learning to enhance operational efficiency and predictive maintenance, as well as the use of big data analytics to optimize production processes. For instance, in February 2024, Digi International unveiled the Digi IX40, a cutting-edge industrial IoT cellular router solution designed for 5G edge computing. This innovative product targets applications such as advanced robotics, predictive maintenance, asset monitoring, industrial automation, and smart manufacturing, catering to the evolving needs of industrial sectors for enhanced connectivity and operational efficiency.

Opportunities in the market abound for companies offering IoT devices, industrial robots, and digital twins. Additionally, the demand for cybersecurity solutions is rising to protect interconnected systems from potential threats. For instance, in June 2021, Broadcom Inc. introduced Adaptive Protection, a novel security solution integrated into Symantec’s Endpoint Security offering. This advanced solution utilizes machine learning (ML) technology to deliver tailored and automated cybersecurity defenses, effectively safeguarding against cyber threats.

By harnessing artificial intelligence (AI), the solution optimizes endpoint security measures, thereby reducing operational expenses for customers through personalized protection strategies. Growth drivers include the need for cost reduction, improved productivity, and flexibility in manufacturing processes. Companies are also motivated by the potential to create customized products quickly and respond swiftly to market demands, thereby gaining a competitive edge.

Industry 4.0 Market Dynamic

Growth Driver-

Increasing Adoption of Internet of Things (IoT) Technologies Across Industrial Sectors

IoT facilitates the interconnectivity of machines, devices, and systems, enabling real-time data collection, analysis, and decision-making. This interconnectedness enhances operational efficiency by streamlining processes, reducing downtime through predictive maintenance, and optimizing resource utilization. Industries are leveraging IoT to create smart factories and supply chains, where interconnected devices communicate seamlessly to improve production quality and meet evolving consumer demands. Additionally, IoT-driven insights empower businesses to innovate their products and services, driving competitive advantage and fostering a more agile and responsive industrial ecosystem poised for sustained growth in the era of digital transformation.

For instance, in January 2024, Bharti Airtel revealed plans to deploy smart metering solutions for Adani Energy Solutions Limited (AESL), enabling connectivity for more than 20 million smart meters. Utilizing NB-IoT, 4G, and 2G technologies, Airtel aims to facilitate seamless communication between these meters and AESL’s central applications. This initiative is set to enhance operational efficiency by enabling real-time data transmission, ensuring uninterrupted monitoring and management of energy consumption.

Trends-

Convergence of Artificial Intelligence (AI) and Robotics to Enhance Automation Capabilities

This trend involves integrating AI technologies such as machine learning and computer vision into robotic systems, enabling them to perform complex tasks with greater precision and autonomy. AI-driven robotics are revolutionizing manufacturing and industrial processes by optimizing production workflows, improving product quality through advanced analytics, and enabling adaptive manufacturing setups that respond dynamically to changing demands. Moreover, AI-powered robots are enhancing safety in workplaces by taking on hazardous tasks and collaborating seamlessly with human workers.

As industries increasingly embrace these AI-enabled robotics solutions, they are poised to achieve higher levels of efficiency, flexibility, and innovation in their operations, driving the evolution towards smarter and more interconnected industrial environments. For instance, in January 2024, PROVEN Robotics introduced its latest AI service robot, OrionStar Mini. This innovative robot is engineered to deliver interactive experiences and operates using the Qualcomm Snapdragon 845 SOC chip, emphasizing advanced processing power and capabilities.

Challenge-

Cybersecurity Vulnerabilities Inherent in Interconnected Industrial Systems

As industries digitize and adopt IoT, AI, and cloud computing technologies, the attack surface for cyber threats expands, exposing critical infrastructure and sensitive data to potential breaches and malicious activities. Ensuring robust cybersecurity measures becomes paramount to safeguard against ransomware, data breaches, and operational disruptions. Moreover, the complexity of integrating diverse technologies from multiple vendors increases the risk of vulnerabilities and compatibility issues, requiring stringent standards and protocols for secure communication and data protection. Addressing these cybersecurity challenges demands continuous investment in advanced threat detection, encryption techniques, and employee training to mitigate risks and build resilient digital infrastructures capable of withstanding evolving cyber threats in the rapidly advancing landscape of Industry 4.0.

Industry 4.0 Market Segmentation by Component, Technology, Industry Vertical, Region

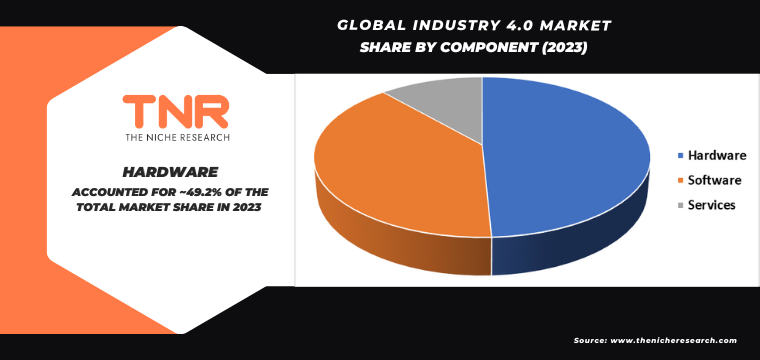

Hardware segment by component is set to dominate the industry 4.0 market, commanding a substantial revenue share of 49.2% over the forecast period. This dominance is driven by the critical role of hardware components such as sensors, actuators, industrial robots, and communication devices in enabling the digital transformation of industries. These components form the backbone of smart manufacturing, facilitating real-time data collection, process automation, and seamless connectivity across industrial ecosystems. As industries increasingly invest in upgrading their infrastructure with advanced hardware solutions, they enhance operational efficiency, optimize resource utilization, and improve product quality. The robust growth of the hardware segment underscores its pivotal role in shaping the future of Industry 4.0 through technological innovation and industrial automation advancements.

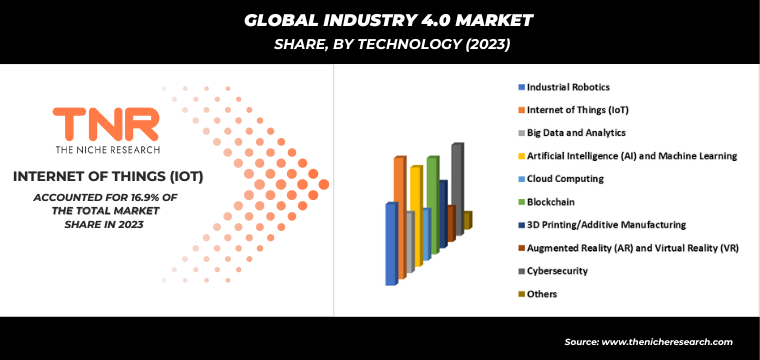

Artificial intelligence (AI) and machine learning segment dominated the market and is anticipated to be the fastest-growing technology in the industry 4.0 market, capturing a substantial revenue share of 13.9% over the forecast period.

This robust expansion is driven by the transformative impact of AI and machine learning technologies across various industrial sectors. AI algorithms enhance operational efficiency by enabling predictive maintenance, optimizing production processes, and facilitating data-driven decision-making. Machine learning capabilities further bolster these advancements by continuously refining algorithms based on real-time data insights, thereby improving precision and adaptability in industrial operations. As industries increasingly harness AI and machine learning to automate tasks, reduce costs, and innovate product offerings, they are poised to unlock new levels of productivity and competitiveness in the evolving landscape of Industry 4.0.

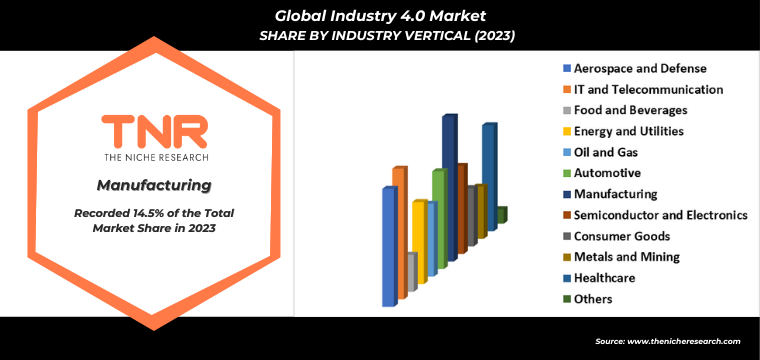

Manufacturing segment by industry vertical dominated the industry 4.0 market, accounting for a significant revenue share of 14.5%.

This leadership position underscores the sector’s pivotal role in driving the adoption of advanced technologies aimed at enhancing operational efficiency and productivity. Industry 4.0 initiatives in manufacturing leverage cutting-edge technologies such as IoT, robotics, AI, and big data analytics to streamline production processes, optimize supply chain management, and improve product quality. These innovations enable manufacturers to achieve higher levels of automation, real-time monitoring, and predictive maintenance, thereby reducing downtime and operational costs while meeting the increasingly complex demands of global markets. As manufacturing industries continue to embrace digital transformation, they are poised to maintain their leadership in shaping the future of Industry 4.0 through innovation and technological integration.

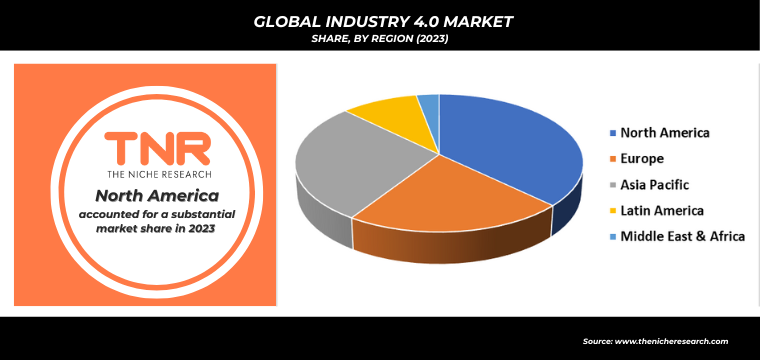

In 2023, North America is anticipated to play a significant role in propelling the growth of the industry 4.0 market, contributing approximately 36.1% to its overall expansion.

This region’s leadership role stems from robust investments and adoption of advanced technologies like IoT, AI, and automation across various industries including manufacturing, healthcare, and automotive. North American enterprises are increasingly deploying Industry 4.0 solutions to enhance operational efficiency, improve supply chain management, and innovate product development processes. Government initiatives supporting digital transformation and favorable economic conditions further bolster the region’s position as a global hub for technological innovation and industrial automation. With a strong ecosystem of technology providers, research institutions, and skilled workforce, North America is poised to continue driving forward the evolution and adoption of Industry 4.0 technologies on a significant scale.

Key Developments

- In January 2024, Renault Group and Atos are teaming up to introduce a unique service aimed at gathering extensive manufacturing data to enhance operational performance within Industry 4.0.

- In September 2023, SSAFE launched a comprehensive Industry 4.0 safety guide, offering insights into implementing advanced technologies across the food supply chain, from farm to consumer.

- In October 2020, Siemens unveiled its expansion plans in India’s Industry 4.0 sector, launching four MindSphere Application Centers. These centers are strategically located in cities like Pune, Gurgaon, and Noida. Siemens operates a global network of approximately 20 centers dedicated to Industry 4.0 solutions, catering to digital customer applications in 17 countries worldwide.

Major Players in Industry 4.0 Market

- ABB LTD.

- Cisco Systems Inc.

- Cognex Corporation

- Denso Corporation

- Emerson Electric

- Fanuc Corporation

- General Electric Company

- Honeywell International Inc.

- IBM

- Intel Corporation

- Johnson Controls International

- Kuka Group

- Robert Bosch GmbH

- Rockwell Automation Inc.

- SAP

- Schneider Electric SE

- Siemens AG

- Other Industry Participants

Global Industry 4.0 Market Scope

| Report Specifications | Details |

| Market Revenue in 2023 | US$ 149.3 Bn |

| Market Size Forecast by 2034 | US$ 1,002.8 Bn |

| Growth Rate (CAGR) | 18.9% |

| Historic Data | 2016 – 2022 |

| Base Year for Estimation | 2023 |

| Forecast Period | 2024 – 2034 |

| Report Inclusions | Market Size & Estimates, Market Dynamics, Competitive Scenario, Trends, Growth Factors, Market Determinants, Key Investment Segmentation, Product/Service/Solutions Benchmarking |

| Segments Covered | By Component, By Technology, By Industry Vertical, By Region |

| Regions Covered | North America, Europe, Asia Pacific, Middle East & Africa, Latin America |

| Countries Covered | U.S., Canada, Mexico, Rest of North America, France, The UK, Spain, Germany, Italy, Nordic Countries (Denmark, Finland, Iceland, Sweden, Norway), Benelux Union (Belgium, The Netherlands, Luxembourg), Rest of Europe, China, Japan, India, New Zealand, Australia, South Korea, Southeast Asia (Indonesia, Thailand, Malaysia, Singapore, Rest of Southeast Asia), Rest of Asia Pacific, Saudi Arabia, UAE, Egypt, Kuwait, South Africa, Rest of Middle East & Africa, Brazil, Argentina, Rest of Latin America |

| Key Players | ABB LTD., Cisco Systems Inc., Cognex Corporation, Denso Corporation, Emerson Electric, Fanuc Corporation, General Electric Company, Honeywell International Inc., IBM, Intel Corporation, Johnson Controls International, Kuka Group, Robert Bosch GmbH, Rockwell Automation Inc., SAP, Schneider Electric SE, Siemens AG |

| Customization Scope | Customization allows for the inclusion/modification of content pertaining to geographical regions, countries, and specific market segments. |

| Pricing & Procurement Options | Explore purchase options tailored to your specific research requirements |

| Contact Details | Consult With Our Expert

Japan (Toll-Free): +81 663-386-8111 South Korea (Toll-Free): +82-808- 703-126 Saudi Arabia (Toll-Free): +966 800-850-1643 United Kingdom: +44 753-710-5080 United States: +1 302-232-5106 E-mail: askanexpert@thenicheresearch.com

|

Global Industry 4.0 Market

By Component

- Hardware

- Software

- Services

By Technology

- Industrial Robotics

- Internet of Things (IoT)

- Big Data and Analytics

- Artificial Intelligence (AI) and Machine Learning

- Cloud Computing

- Blockchain

- 3D Printing/Additive Manufacturing

- Augmented Reality (AR) and Virtual Reality (VR)

- Cybersecurity

- Others

By Industry Vertical

- Aerospace and Defense

- IT and Telecommunication

- Food and Beverages

- Energy and Utilities

- Oil and Gas

- Automotive

- Manufacturing

- Semiconductor and Electronics

- Consumer Goods

- Metals and Mining

- Healthcare

- Others

By Region

- North America (U.S., Canada, Mexico, Rest of North America)

- Europe (France, The UK, Spain, Germany, Italy, Nordic Countries (Denmark, Finland, Iceland, Sweden, Norway), Benelux Union (Belgium, The Netherlands, Luxembourg), Rest of Europe)

- Asia Pacific (China, Japan, India, New Zealand, Australia, South Korea, Southeast Asia (Indonesia, Thailand, Malaysia, Singapore, Rest of Southeast Asia), Rest of Asia Pacific)

- Middle East & Africa (Saudi Arabia, UAE, Egypt, Kuwait, South Africa, Rest of Middle East & Africa)

- Latin America (Brazil, Argentina, Rest of Latin America)

Report Layout:

Table of Contents

Note: This ToC is tentative and can be changed according to the research study conducted during the course of report completion.

**Exclusive for Multi-User and Enterprise User.

Global Industry 4.0 Market

By Component

- Hardware

- Software

- Services

By Technology

- Industrial Robotics

- Internet of Things (IoT)

- Big Data and Analytics

- Artificial Intelligence (AI) and Machine Learning

- Cloud Computing

- Blockchain

- 3D Printing/Additive Manufacturing

- Augmented Reality (AR) and Virtual Reality (VR)

- Cybersecurity

- Others

By Industry Vertical

- Aerospace and Defense

- IT and Telecommunication

- Food and Beverages

- Energy and Utilities

- Oil and Gas

- Automotive

- Manufacturing

- Semiconductor and Electronics

- Consumer Goods

- Metals and Mining

- Healthcare

- Others

By Region

- North America (U.S., Canada, Mexico, Rest of North America)

- Europe (France, The UK, Spain, Germany, Italy, Nordic Countries (Denmark, Finland, Iceland, Sweden, Norway), Benelux Union (Belgium, The Netherlands, Luxembourg), Rest of Europe)

- Asia Pacific (China, Japan, India, New Zealand, Australia, South Korea, Southeast Asia (Indonesia, Thailand, Malaysia, Singapore, Rest of Southeast Asia), Rest of Asia Pacific)

- Middle East & Africa (Saudi Arabia, UAE, Egypt, Kuwait, South Africa, Rest of Middle East & Africa)

- Latin America (Brazil, Argentina, Rest of Latin America)

The Niche Research approach encompasses both primary and secondary research methods to provide comprehensive insights. While primary research is the cornerstone of our studies, we also incorporate secondary research sources such as company annual reports, premium industry databases, press releases, industry journals, and white papers.

Within our primary research, we actively engage with various industry stakeholders, conducting paid interviews and surveys. Our meticulous analysis extends to every market participant in major countries, allowing us to thoroughly examine their portfolios, calculate market shares, and segment revenues.

Our data collection primarily focuses on individual countries within our research scope, enabling us to estimate regional market sizes. Typically, we employ a bottom-up approach, meticulously tracking trends in different countries. We analyze growth drivers, constraints, technological innovations, and opportunities for each country, ultimately arriving at regional figures.Our process begins by examining the growth prospects of each country. Building upon these insights, we project growth and trends for the entire region. Finally, we utilize our proprietary model to refine estimations and forecasts.

Our data validation standards are integral to ensuring the reliability and accuracy of our research findings. Here’s a breakdown of our data validation processes and the stakeholders we engage with during our primary research:

- Supply Side Analysis: We initiate a supply side analysis by directly contacting market participants, through telephonic interviews and questionnaires containing both open-ended and close-ended questions. We gather information on their portfolios, segment revenues, developments, and growth strategies.

- Demand Side Analysis: To gain insights into adoption trends and consumer preferences, we reach out to target customers and users (non-vendors). This information forms a vital part of the qualitative analysis section of our reports, covering market dynamics, adoption trends, consumer behavior, spending patterns, and other related aspects.

- Consultant Insights: We tap into the expertise of our partner consultants from around the world to obtain their unique viewpoints and perspectives. Their insights contribute to a well-rounded understanding of the markets under investigation.

- In-House Validation: To ensure data accuracy and reliability, we conduct cross-validation of data points and information through our in-house team of consultants and utilize advanced data modeling tools for thorough verification.

The forecasts we provide are based on a comprehensive assessment of various factors, including:

- Market Trends and Past Performance (Last Five Years): We accurately analyze market trends and performance data from preceding five years to identify historical patterns and understand the market’s evolution.

- Historical Performance and Growth of Market Participants: We assess the historical performance and growth trajectories of key market participants. This analysis provides insights into the competitive landscape and individual company strategies.

- Market Determinants Impact Analysis (Next Eight Years): We conduct a rigorous analysis of the factors that are projected to influence the market over the next eight years. This includes assessing both internal and external determinants that can shape market dynamics.

- Drivers and Challenges for the Forecast Period:Identify the factors expected to drive market growth during the forecast period, as well as the challenges that the industry may face. This analysis aids in deriving an accurate growth rate projection.

- New Acquisitions, Collaborations, or Partnerships: We keep a close watch on any new acquisitions, collaborations, or partnerships within the industry. These developments can have a significant impact on market dynamics and competitiveness.

- Macro and Micro Factors Analysis:A thorough examination of both macro-level factors (e.g., economic trends, regulatory changes) and micro-level factors (e.g., technological advancements, consumer preferences) that may influence the market during the forecast period.

- End-User Sentiment Analysis: To understand the market from the end-user perspective, we conduct sentiment analysis. This involves assessing the sentiment, preferences, and feedback of the end-users, which can provide valuable insights into market trends.

- Perspective of Primary Participants: Insights gathered directly from primary research participants play a crucial role in shaping our forecasts. Their perspectives and experiences provide valuable qualitative data.

- Year-on-Year Growth Trend: We utilize a year-on-year growth trend based on historical market growth and expected future trends. This helps in formulating our growth projections, aligning them with the market’s historical performance.

Research process adopted by TNR involves multiple stages, including data collection, validation, quality checks, and presentation. It’s crucial that the data and information we provide add value to your existing market understanding and expertise. We have also established partnerships with business consulting, research, and survey organizations across regions and globally to collaborate on regional analysis and data validation, ensuring the highest level of accuracy and reliability in our reports.